Jenoptik: Test Stations for Precision Punching Production

Jenoptik is a specialist in everything to do with photonics. Lasers, optics, optical circuits, image processing and camera technology. At Blechexpo 2023, the company wins an innovation award with a test station for punching production.

Specialist for all types of photonics

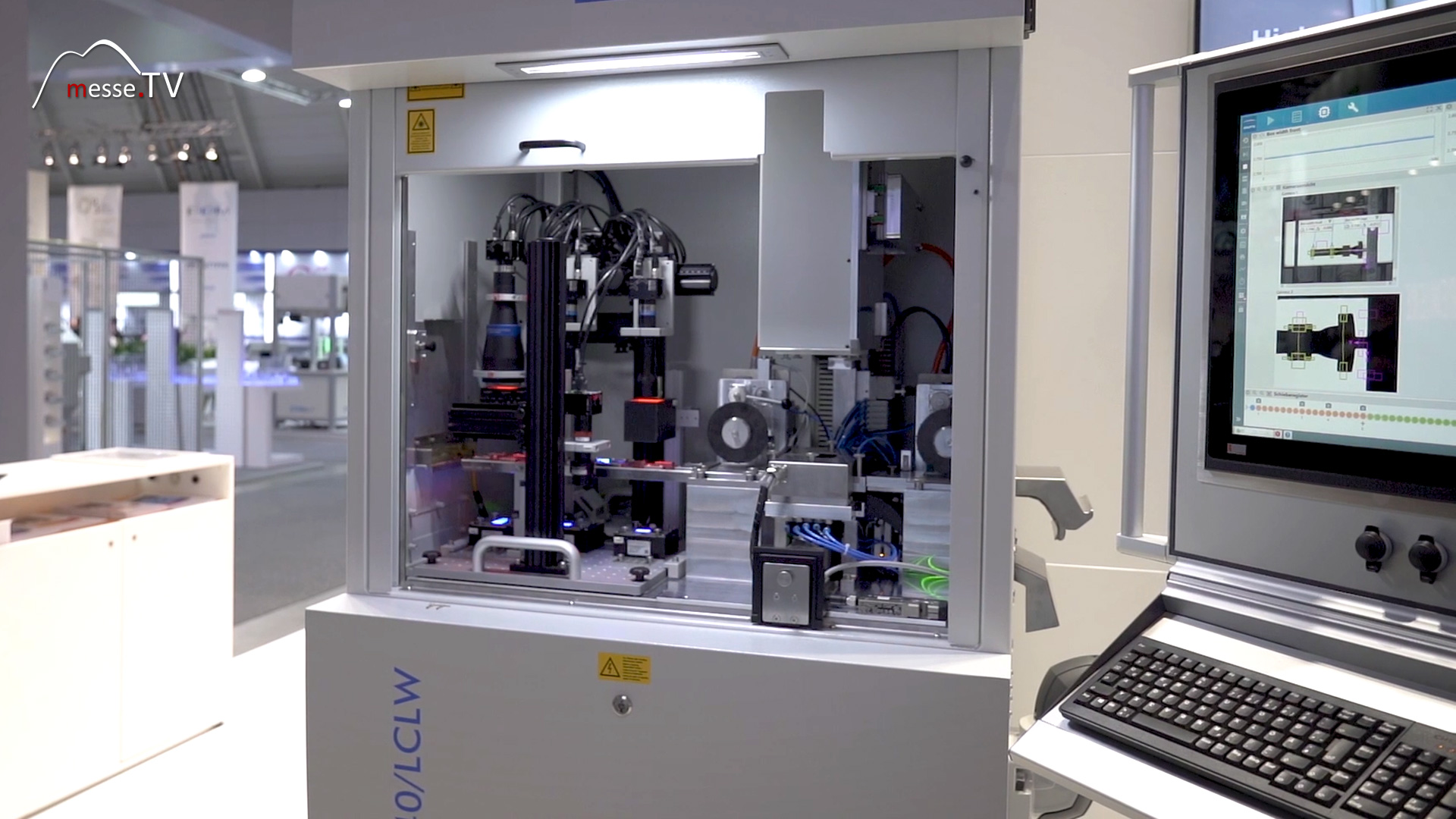

Jenoptik specializes in photonics of all kinds, such as lasers, optics, optical circuits, image processing and camera technology. A new type of testing station for stamping production wins the company an innovation award at Blechexpo 2023. Jenoptik has been involved in stamping technology for many years, particularly in contact production. The parts are 100% tested in production at full stroke rate. Mr. Ekkehard Fluck, responsible for Advanced Photonic Solutions at Jenoptik, is delighted with the Innovation Award for the special innovation, which he shows and describes in more detail below.

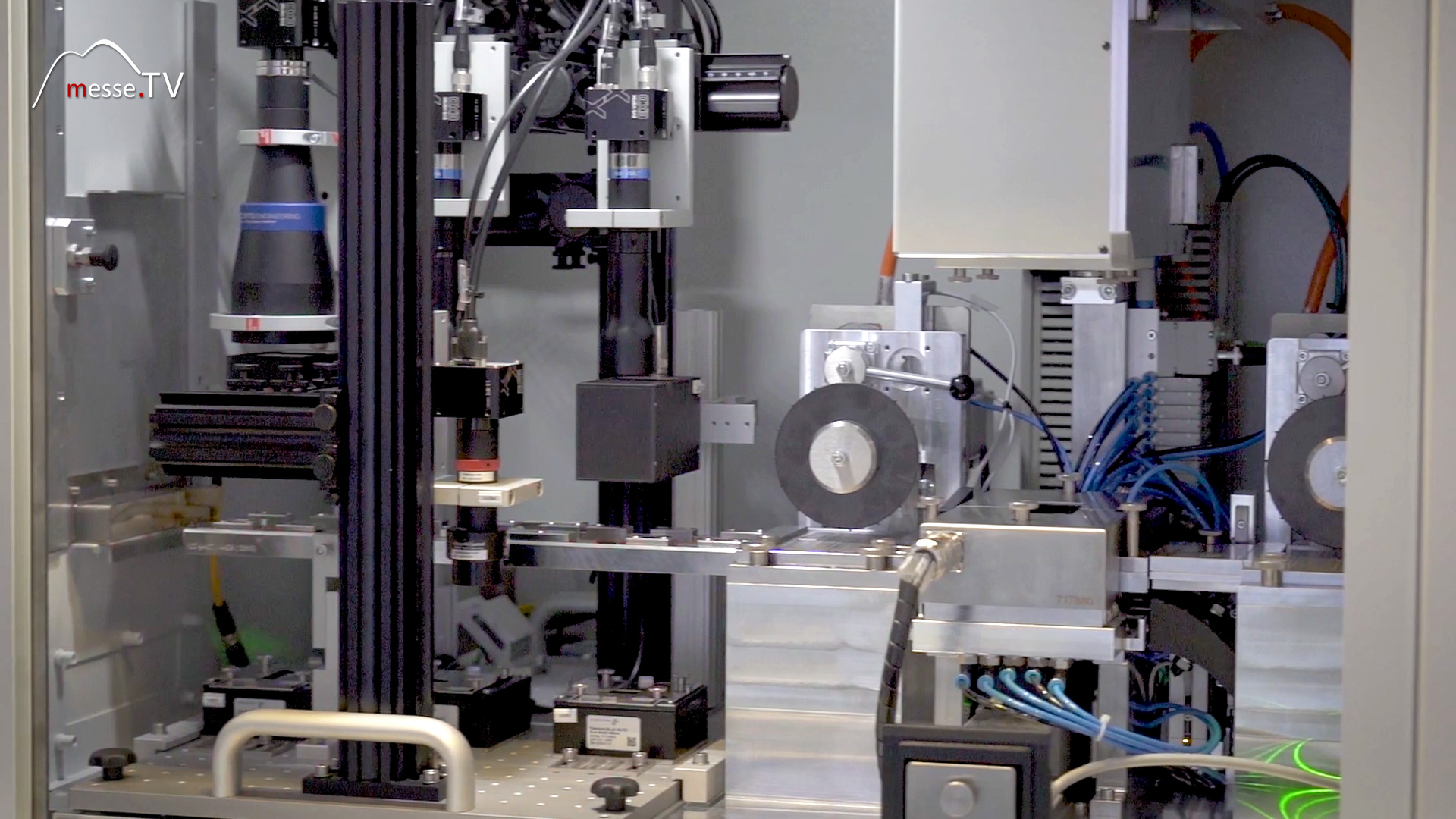

Inspection station for punching strips in laser cutting and laser welding PSS 40

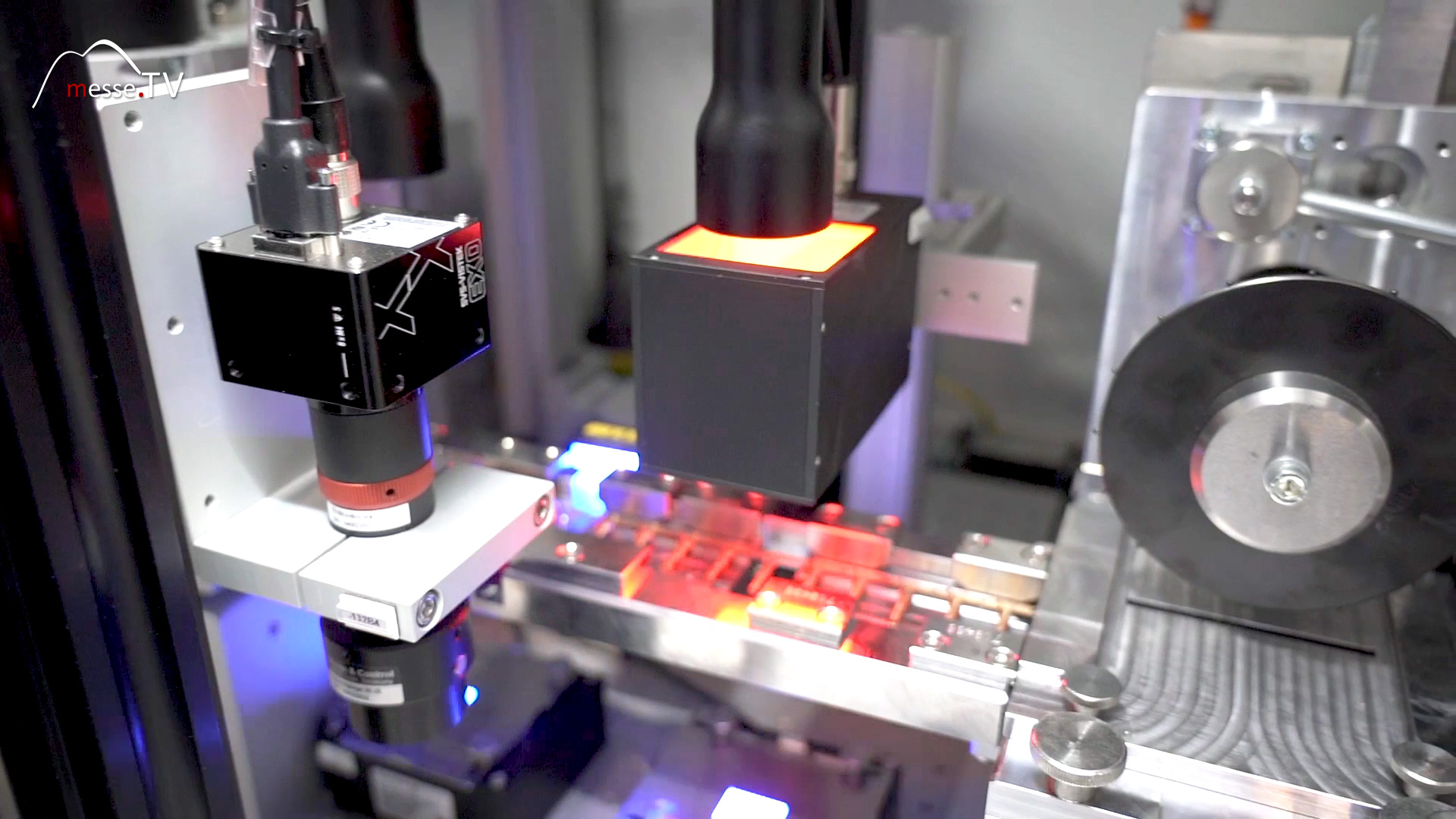

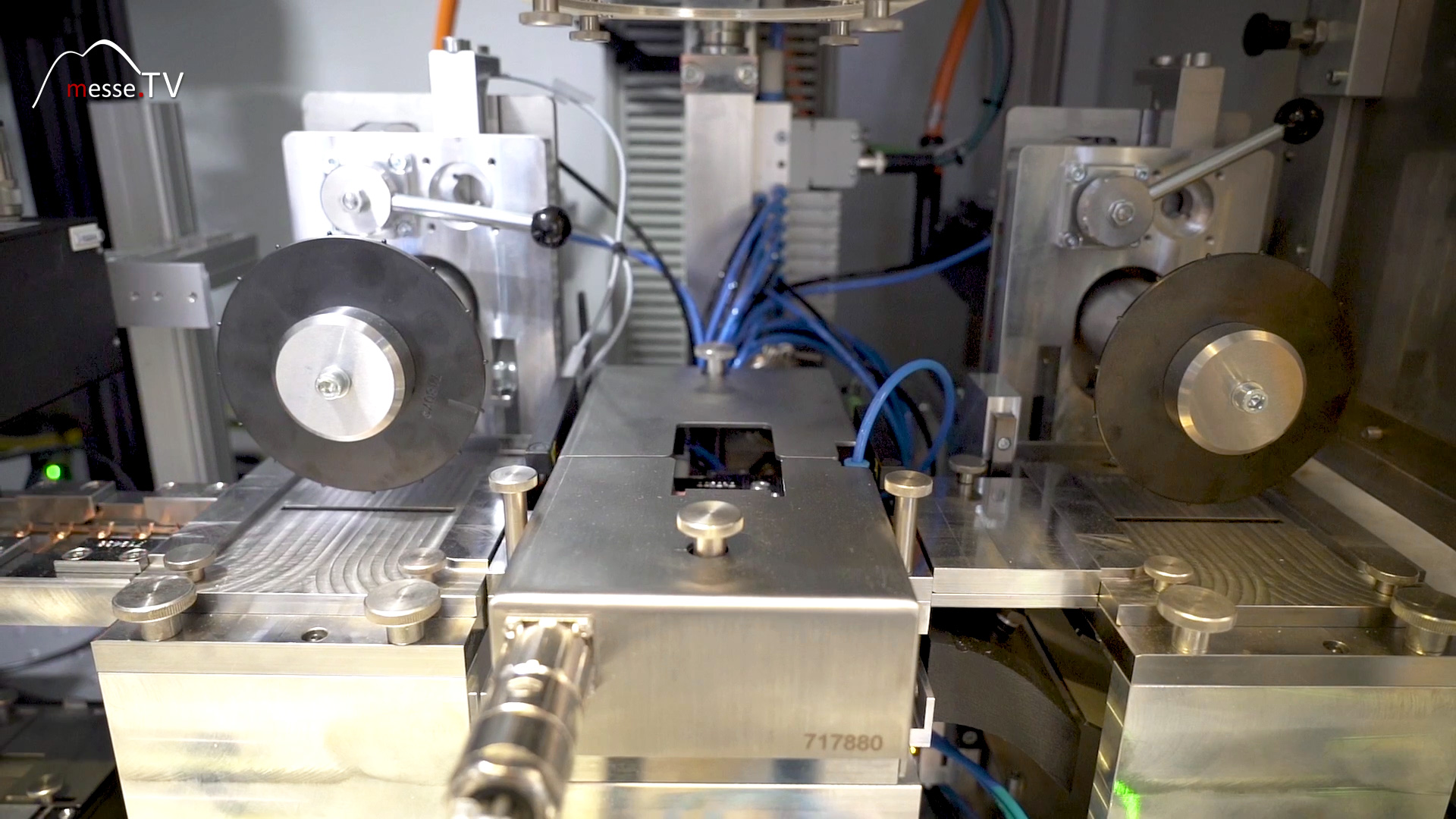

It is a PSS 40 test station for punching strips in laser cutting and laser welding, i.e. laser cutting and laser welding. This is all done in one using the built-in laser. He demonstrates the function with a typical punched contact part, as produced by the customer in enormous quantities. The image processing of the PSS 40 inspection station detects defects, dimensional errors or deviations, which are then cut out completely by laser. The strip is reconnected and welded together. This is followed by a tensile test and a camera documents the welding process. The customer can now be sure that only good parts are on his coil.

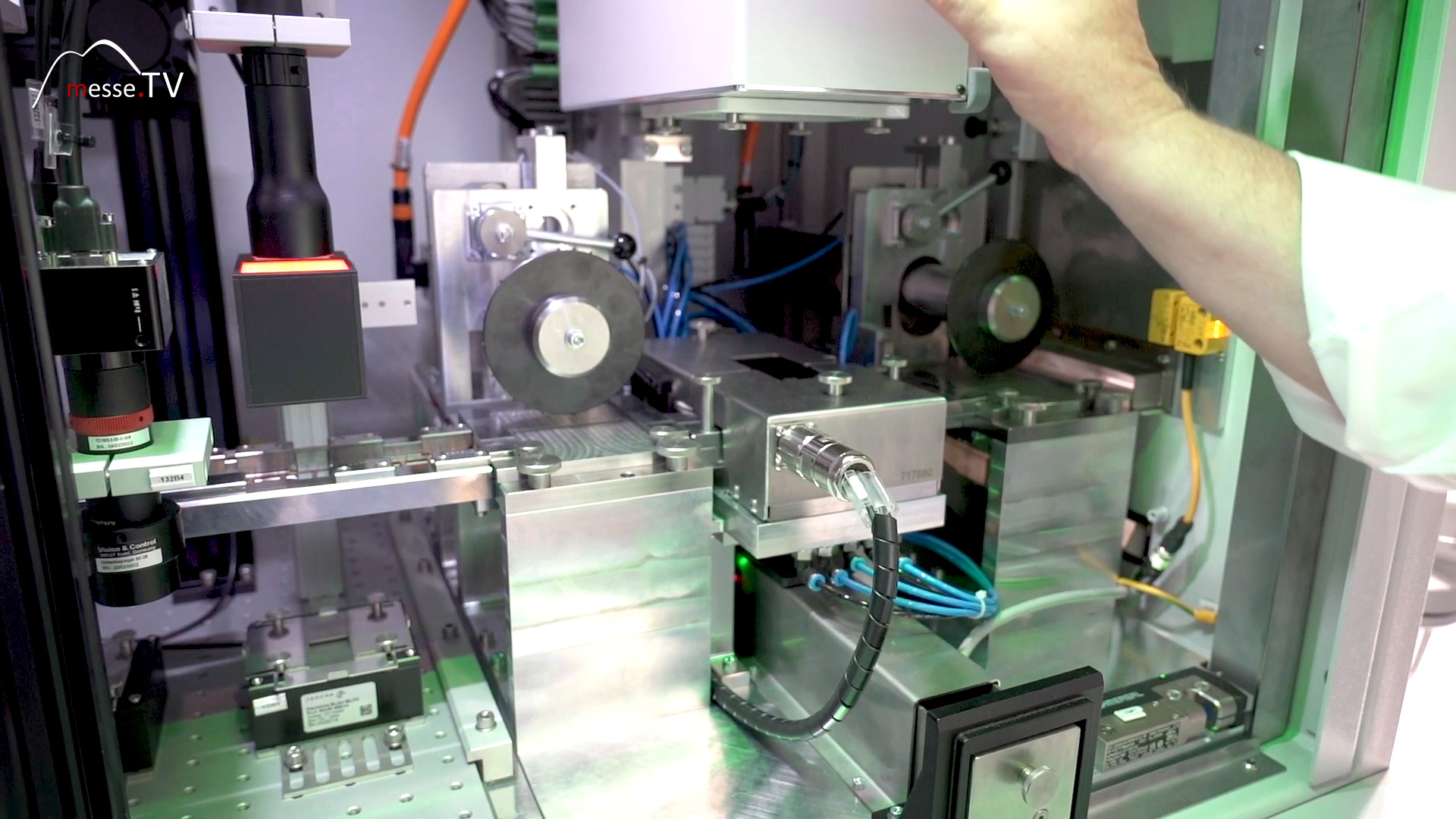

The punched part is recorded from different angles

The workflow looks like this: When the punched part comes out of the press, it is brought into the machine through the infeed, goes into a strip guide where the cameras, lenses and lights are mounted. The punched part is captured from different angles, just as it would be viewed under a projector. Once the various cameras have captured all perspectives, a first drive wheel pulls the strip through the machine and guides it to a laser unit that can cut out the defective part. A second drive wheel brings the part back together and the same laser welds the two parts together again. The two drive wheels then work against each other for a tensile test. A final photo is automatically taken for documentation purposes.

First machine on the market that cuts and welds with a single laser

The PSS 40 is the first machine on the market that actually cuts and welds with a single laser. An absolute innovation. Previously, damaged areas had to be cut out mechanically and then welded with the laser. The disadvantage of this method is that mechanical cuts always result in changes to the edge. This weakens the laser welding spot or the laser welding line. This is not the case with the PSS 40 inspection station - it works wear-free around the clock without any problems.